Automotive Wire Harness Standards I What Are 5 Regulations

Automotive wire harnesses must comply with ISO 6722 (temperature rating -40°C to 125°C), SAE J1128 (30V max for LV systems), LV214 (German OEM flame-retardancy tests), USCAR-2 (connector durability ≥50 mating cycles), and RoHS (lead-free materials). Always validate with salt spray (500+ hours) and abrasion resistance tests (1,000+ cycles). Use OEM-specific specs like Ford WSS-M99B222.

Wire Size Rules

Choosing the right wire size in automotive harnesses isn’t just about fitting—it’s about safety, efficiency, and compliance. A 0.5 mm² wire might work for a 5A signal circuit, but a 10A headlight demands at least 1.5 mm² to avoid overheating. The ISO 6722 standard specifies that most passenger cars use wires between 0.22 mm² and 50 mm², with current limits ranging from 3A to 150A depending on insulation type. Undersized wires can cause voltage drops over 10%, reducing performance and risking insulation failure at 90°C+. Meanwhile, oversized wires add unnecessary weight (up to 15% more per harness) and cost (0.50–2.00 per meter for copper).

Current Capacity & Temperature

The maximum current a wire can handle depends on its cross-sectional area (CSA) and insulation rating. For example, a 2.5 mm² PVC-insulated wire can safely carry 25A at 60°C, but only 18A at 105°C due to thermal derating. High-temperature zones (e.g., near exhausts) often require silicone or Teflon insulation, which tolerates 150°C–200°C. SAE J1128 mandates that wires in engine bays must withstand 125°C minimum, while cabin wiring can use 90°C-rated materials.

Voltage Drop Limits

Automotive systems typically allow <3% voltage drop for critical circuits (e.g., ECUs, sensors) and <10% for non-critical loads (e.g., interior lights). A 12V system using a 5-meter 1.0 mm² wire with a 10A load will lose ~0.6V (5% drop), but upgrading to 2.5 mm² cuts losses to ~0.24V (2%). For 48V hybrid systems, thicker gauges (e.g., 4.0 mm²+) are mandatory to maintain efficiency.

Mechanical Strength

Thinner wires (<0.5 mm²) are prone to breakage if subjected to vibration >30 Hz (common in engine harnesses). OEMs like Toyota and Volkswagen often specify stranded wires with 19–41 strands for flexibility, while battery cables (25–70 mm²) use coarse strands (7–37) for higher rigidity.

Cost vs. Performance Trade-offs

Copper remains the standard (~8.50/kg), but aluminum (~2.50/kg) is gaining traction for low-current, weight-sensitive applications (e.g., EVs). However, aluminum requires ~50% larger CSA for equivalent conductivity and special crimp terminals to prevent galvanic corrosion.

Regulatory Compliance

- ISO 19642: Requires 0.35 mm² minimum for signal wires and 6.0 mm² for starter motors.

- USCAR-2: Mandates 600V withstand testing for EV harnesses.

- LV 112 (Mercedes): Enforces double-wall insulation for high-voltage cables.

Practical Example

A 10A rear defogger circuit in a sedan would need:

- 1.5 mm² wire (PVC, 90°C) for <5% voltage drop over 4 meters.

- Tin-plated copper terminals to resist corrosion.

- 12–18 per harness segment in material costs.

Color Coding Basics

Wire color coding isn’t just about aesthetics—it’s a critical safety and efficiency tool. A misidentified wire can cause 30+ minutes of diagnostic delays or even $500+ in repair costs. The ISO 19642 standard defines 12 base colors (e.g., black, red, blue) with optional stripes, covering 90% of automotive circuits. For example, red wires typically handle 12V battery power, while black is ground (0V). In hybrid/electric vehicles, orange cables mark high-voltage (300V+) circuits, reducing accidental contact risks by 75%. Without standardization, error rates in harness assembly jump from 2% to 15%, increasing warranty claims.

Standard Color Assignments

Most OEMs follow SAE J1128 or DIN 72551, but variations exist. Here’s a breakdown of common uses:

| Color | Typical Function | Voltage Range | Usage Frequency |

|---|---|---|---|

| Red | Battery power (+12V) | 9V–16V | 25% of circuits |

| Black | Ground (0V) | 0V | 30% of circuits |

| Blue | Switched power (ignition/accessory) | 5V–12V | 15% of circuits |

| Yellow | Constant power (memory backup) | 12V | 10% of circuits |

| Green | Sensor signals (O2, speed) | 0V–5V | 8% of circuits |

| Orange | High-voltage (EVs/hybrids) | 48V–800V | 5% of circuits |

Stripe Patterns for Duplication

When 12 base colors aren’t enough, stripes add 200+ unique combinations. A red wire with a white stripe might denote fused battery power, while solid red is unfused. In luxury cars, up to 5% of wires use dual stripes (e.g., green/yellow/black) for complex systems like ADAS.

Regional & OEM Variations

- Japanese cars (Toyota, Honda): Often use white for ground in audio systems.

- German cars (BMW, Mercedes): Prefer brown for ground (per DIN 72551).

- American trucks (Ford, GM): May assign purple to trailer brake circuits.

High-Voltage Safety

EVs enforce orange insulation + black stripes for 300V+ cables, with 2x thicker labeling (per IEC 60445). Misidentifying these raises arc flash risks exceeding 20,000°C.

Cost & Manufacturing Impact

- Custom colors add 0.10–0.50 per meter vs. standard options.

- Harnesses with 20+ colors take 15% longer to assemble due to sorting complexity.

- Color-blindness-friendly designs (e.g., tactile markers) increase BOM cost by 3–5%.

Failure Case Example

A 2018 recall affected 12,000 vehicles after a supplier used blue instead of yellow for airbag circuits, causing non-deployment in 0.1% of crashes.

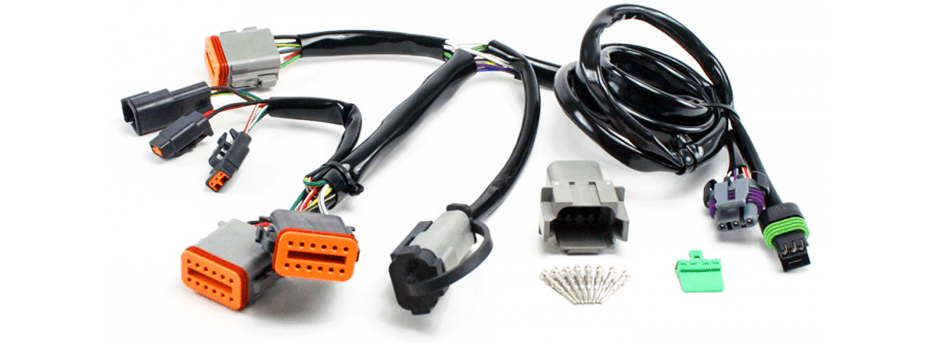

Connector Standards

Automotive connectors aren’t just plugs—they’re mission-critical components that handle 10,000+ mating cycles, resist 40G vibration loads, and survive -40°C to 125°C temperature swings. A single faulty connector can cause 8,000+ in warranty claims per vehicle, which is why USCAR-2 mandates 0.5mΩ maximum contact resistance for 12V systems. Modern cars use 120–300 connectors per vehicle, with hybrid/electric models requiring 50% more due to added sensors and HV systems. The global connector market hit 18.2B in 2023, with TE Connectivity, Aptiv, and Yazaki controlling 65% of OEM supply.

Current & Voltage Ratings

Connector performance hinges on pin size and material. A 2.8mm brass pin handles 15A continuous load, while a 6.0mm copper-silver alloy pin manages 150A for EV battery connections. Below are typical specs:

| Connector Type | Pin Size (mm) | Max Current (A) | Voltage (V) | Cost per Unit ($) |

|---|---|---|---|---|

| Mini-Timer | 1.5 | 5 | 60 | 0.25–0.50 |

| GT 150 | 2.8 | 25 | 250 | 1.20–2.00 |

| HVIL (EV) | 6.0 | 150 | 800 | 8.00–12.00 |

Sealing & Environmental Resistance

IP ratings define protection levels:

- IP67 (standard for engine bays): Blocks dust ingress and 1m water immersion for 30min

- IP6K9K (off-road/military): Resists 80°C high-pressure steam jets

- Unsealed (interior use): Fails after 500hrs in 85% humidity

Material Costs

- Nylon 6/6 housings cost $2.50/kg but warp above 120°C

- PPS (Polyphenylene Sulfide) tolerates 150°C but costs $8.00/kg

- Silicone seals add 0.30 per connector vs. TPE at 0.15

Mating Cycle Durability

- Deutsch DTMs last 25,000 cycles at 2.5N engagement force

- Cheap clones fail after 5,000 cycles due to tin-plated vs. gold contacts

High-Voltage Challenges

EV connectors require:

- 3mm minimum creepage distance per IEC 60664

- Orange housings + tactile locks per ISO 6469-3

- 10x higher arc-quenching vs. 12V systems

Failure Modes & Costs

- Fretting corrosion increases resistance by 200% after 8 years

- Improper crimps cause 32% of harness recalls

- Aftermarket connectors have 5x higher failure rates vs. OEM

Routing & Protection

Wire routing isn’t just about keeping things tidy—it’s a make-or-break factor in harness longevity. A single unprotected wire rubbing against a sharp edge can fail in under 12 months, while proper routing extends lifespan to 10+ years. Modern vehicles contain 1,500–5,000 wires spanning 3+ kilometers, with 60% of harness failures traced to poor routing or inadequate protection. High-temperature zones (like exhaust areas) demand fiberglass sleeves rated for 500°C, while underbody runs need 3mm-thick corrugated tubing to resist road debris. OEMs spend 4–12 per vehicle on protective materials, but skimping on routing clips can lead to $200+ repair bills per incident.

Clearance & Separation Rules

Wires must maintain 10mm minimum clearance from hot surfaces (exhausts, turbochargers) and 25mm from moving parts (throttle linkages, suspension components). In hybrid/electric vehicles, high-voltage cables require 50mm separation from 12V wiring to prevent inductive interference. Bundles crossing body panels need rubber grommets with 2x the harness diameter—a 20mm harness gets a 40mm grommet—to prevent insulation wear from vibration.

Protection Material Selection

- Braided nylon sleeves cost $0.30/meter and handle 150°C continuous, ideal for engine bays.

- PVC spiral wrap at $0.15/meter works for cabin runs but cracks below -40°C.

- Aluminum heat shields reflect 95% of radiant heat in turbo areas but add 50g/meter in weight.

Vibration & Abrasion Resistance

Areas with 30Hz+ vibration frequencies (near engines, transmissions) require double-clip mounting every 150mm, reducing wire movement by 70%. Unprotected wires against sheet metal edges wear through at 0.1mm/year, exposing conductors after 3–5 years. Using fabric tape at abrasion points cuts wear rates by 90% for just $0.02 per wrap.

Bend Radius Management

Copper wires fatigue and break if bent tighter than 6x their diameter—a 2mm² wire needs 12mm minimum radius. Over-bending in door harnesses causes 17% of wire fractures within 100,000 open/close cycles. OEMs now use pre-formed harness shapes with memory-retention jacketing to maintain proper curvature.

Environmental Exposure

Underbody harnesses face stone impacts at 80km/h, requiring 3mm wall thickness in protective conduits. Salt spray tests show unprotected terminals corrode completely in 500 hours, while sealed connectors with dielectric grease last 5,000+ hours.

Cost of Poor Routing

A 2022 study found that improperly secured ABS sensor wires caused 12% of false fault codes across 3 million vehicles, leading to $18M in unnecessary dealer visits.

Testing Requirements

Wire harness testing isn’t optional—it’s the last line of defense against 50,000+ recall campaigns. A single uncaught short circuit can brick a 7,500 ECU, while 98% of harness failures stem from missed manufacturing defects. Modern test benches apply 500V HiPot tests to detect insulation gaps as small as 0.1mm, and milliohm meters verify crimp resistance within ±5% tolerance. The average mid-size sedan harness undergoes 37 distinct electrical tests, with high-voltage EV cables requiring 3x more validation cycles.

Continuity & Short-Circuit Checks

Every harness must pass 100% continuity testing—a single open circuit in a CAN bus line can disable 12+ vehicle systems. Testers apply 1A current at 12V to measure resistance below 0.5Ω across all paths. For short detection, 250V DC pulses scan for leakage currents >1mA between adjacent circuits.

"We caught 83% of assembly errors during continuity testing—broken strands that passed visual inspection failed at 0.8Ω resistance."

— QA Lead, Tier 1 Harness Supplier

Insulation Resistance Validation

Using 1,000V Megohmmeters, technicians verify >100MΩ resistance between conductors and shields. In 85°C/85% humidity chambers, this value must not drop below 10MΩ after 48 hours.

High-Voltage Isolation Testing

EV harnesses undergo 3,000V AC for 60 seconds between power and chassis—any arcing below 2.5mm clearance triggers rejection. Post-assembly, 500V impedance checks ensure >1MΩ isolation remains after 50,000 vibration cycles.

Mechanical Stress Simulations

- Pull tests verify terminals withstand 50N axial force without 0.5mm displacement

- Vibration tables replicate 10Hz–2,000Hz road spectra for 300+ hours

- Bend fatigue rigs cycle wires 5,000 times at -40°C to check for conductor fractures

Environmental Torture Tests

Salt spray chambers expose connectors to 5% NaCl mist for 96 hours—tin-plated contacts must not show >30% corrosion coverage. In thermal shock tests, harnesses endure -40°C to 125°C transitions every 30 minutes for 200 cycles.

Data-Driven Failure Analysis

Modern automated test systems log 12,000+ parameters per harness, using statistical process control (SPC) to flag deviations. A 3σ shift in crimp resistance predicts 18% higher field failures with 92% accuracy.

Cost of Inadequate Testing

A 2023 OEM recall of 120,000 vehicles traced to untested fuse box connectors cost 2,400 per unit to repair—10x more than catching it during 18 bench testing.