The principles that must be followed in the design of automotive wiring harnesses

Introduction

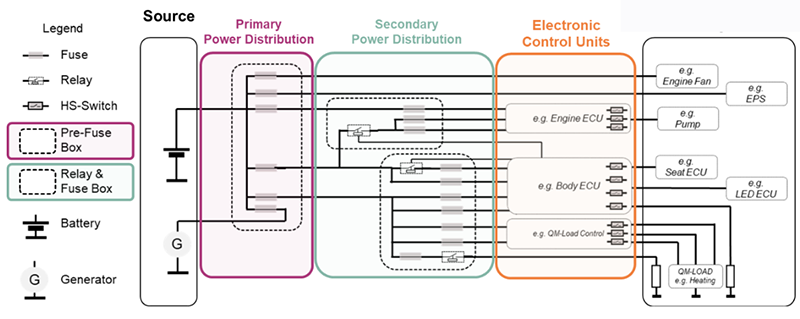

The production process of the automotive wiring harness is more complex, especially the design of automotive wiring harnesses must be more comprehensive and meticulous. If the harness is poorly designed and the functions of each part cannot be organically combined, it is possible to make the harness a frequent occurrence in the automotive fault. Below, Hooha Harness starts from practice and talks about the principles that must be followed in the design of automotive wiring harnesses. First of all, under the vehicle circuit design, the vehicle circuit design can be divided into the design of wiring harness diagram, power distribution design, circuit protection design, relay selection design, and ground distribution design principles. In fact, this is a kind of wire harness layout in the design of automotive wiring harnesses.

1, The design and calculation of the harness diagram

This is the previous work of the automotive wiring harness design. The harness diagram describes the relationship between the various electrical parts, reflecting the size of the electrical components and the distance between them, but also reflecting how the electrical components are connected to each other. Need to calculate electrical power, and also need to calculate the wire diameter.

2, The power distribution design

whether the car's power supply system design is reasonable, is directly related to the normal operation of automotive electrical components and the safety of the entire vehicle, so the world of automotive wiring harness design principles is basically based on safety. The vehicle's electrical system is basically composed of three parts: the battery direct power supply system, the ignition switch-controlled power supply system, and the power source that removes the load when the engine is started.

3, The wire protection design

Wire protection is to protect the wire harness, taking into account the protection of the circuit components. The protection devices mainly include fuses, circuit breakers, and fusible links. The selection of these components must be based on the actual situation and must not be sloppy.

4, The selection of relay design

Relays are generally divided into current and voltage type 2 kinds. The choice of the relay must be based on the power of the appliance and the load-carrying capacity of the switch. Commonly used relays generally have wipers, horns, defrosts, headlamps, fog lamps, fans, blowers, etc. The relay is divided into 6 types of 6V, 12V, and 24V. The commonly used relay has a rated voltage of 12V.

The relay's technical requirements are:

- good reliability;

- stable performance;

- lightweight;

- small size;

- long life;

- small impact on the surrounding components;

- simple structure;

- good process;

- low cost.

5, The principle of ground distribution design

Ground distribution design is very important in the design of automotive wiring harnesses, and is susceptible to interference by other electrical equipment, affecting the functional realization of certain automotive components. Ground distribution design principles should meet the following requirements: Weak signal sensors should be close to the ground to ensure the normal transmission of signals; each ECU should be grounded alone to prevent interference; negative battery ground and battery, gearbox grounding should be carefully considered, Try to think comprehensively.

Following this five-point vehicle wiring harness design principle can ensure the smooth progress of the vehicle circuit design and make the wiring harness layout reasonable.

Hooha Harness Introduction

Hooha Harness is a professional wire harness manufacturer based in China. With over 20 years of experience in customizing wire harnesses, we have become experts in providing OEM and ODM services to our clients worldwide. Our team of skilled engineers and technicians are committed to delivering high-quality products that meet the needs of our customers. We adhere to strict quality standards and carry out IPC/WHMA-A-620 standards for all our wire harnesses. We have also obtained IATF16949, ISO9001, and UL certificates which demonstrate our commitment to quality assurance. Our specialization lies in custom automotive wire harnesses, auto connectors, and power cables. We work closely with our clients to understand their specific requirements and provide tailored solutions that meet their needs.

How to customize your wire harness?

Send your sample or drawing/schematic for quote price→ Feedback with quotation(1~3 days) → Confirm quotation → Arrange sample you for approval→ [Make mold if needed (7 days) →Mold test] → Making samples(1~3 days)→Samples test(Approval) →place order for Mass production(2~3 weeks)→Quality checking→Packing →Delivery →After Service →Repeat Order.