Battery Connector Types

Introduction

In today's technologically advanced world, battery connectors are used in a wide range of applications, each with its own unique requirements. For instance, in the automotive industry, robust battery connectors are necessary to handle high currents and vibrations while providing reliable power transmission for electric vehicles. These connectors not only ensure smooth operation but also contribute to the overall safety of the vehicle.

Similarly, in consumer electronics such as smartphones and laptops, compact yet durable battery connectors are needed to facilitate fast charging and data synchronization. The design of these connectors is often tailored to fit within limited space constraints without compromising on performance or reliability.

Moreover, industrial equipment heavily relies on battery connectors for uninterrupted power supply during critical operations. In sectors like telecommunications or renewable energy systems, where continuous uptime is paramount, specialized high-capacity battery connectors capable of handling large currents become indispensable.

Furthermore, medical devices depend on precise power delivery through reliable battery connections to ensure accurate readings and consistent performance. From life-saving equipment like pacemakers to portable diagnostic tools, these intricate devices require secure connections that can withstand rigorous usage conditions while maintaining optimal functionality.

Type of Battery Connectors

In terms of function, battery connectors can be categorized into two main types: primary and secondary connectors. Primary connectors are designed for one-time use and are commonly found in disposable batteries. On the other hand, secondary connectors are built for repeated connections and disconnections, making them suitable for rechargeable batteries.

Shape-wise, battery connectors can vary from simple pin-type connectors to more complex designs like blade or socket-type connectors. Pin-type connectors feature a cylindrical shape with a protruding pin that fits into corresponding holes on the device or battery terminal. Blade-type connectors have flat metal blades that slide into slots on the device or battery terminal for secure connection. Socket-type connectors consist of hollow cylinders that receive pins or blades from the opposite end.

Battery connector selection also depends on their intended use. For example, automotive applications often require robust and vibration-resistant connections due to harsh operating conditions. In contrast, consumer electronics may prioritize compactness and ease of assembly when choosing battery connector types.

-

- XT30/XT60/XT90 Connectors

- T-plug Connector

- EC2, EC3, EC5, EC6, and EC8 Battery Connectors

- Anderson Powerpole Connector for Battery

- JST Connector

- Molex Connector

- Car Battery Connector

- Solar Power Battery Connector

- 9V Battery Clip Connector

- SAE Battery Connector

- New Energy Battery Connector

XT30/XT60/XT90 Connectors

XT30, XT60, and XT90 connectors are popular choices in the world of electronics for high-current applications. They are designed to provide a secure and reliable connection with minimal resistance, making them ideal for use in a variety of electrical devices. These connectors are typically used to connect batteries to electronic speed controllers (ESCs), chargers, or power distribution boards. The numbers in their names (30, 60, 90) refer to the maximum current rating (in amperes) they can handle.

Features

High Current Carrying Capacity:

- XT30: Rated for up to 30A continuous current.

- XT60: Rated for up to 60A continuous current.

- XT90: Rated for up to 90A continuous current.

High Temperature Resistance:

- Made from durable materials that can withstand high temperatures, ensuring safety and performance even under heavy loads.

Low Resistance:

- Gold-plated connectors provide low resistance, ensuring efficient power transfer and reducing the risk of overheating.

Secure Connection:

- Designed with a tight fit to prevent accidental disconnection, featuring anti-spark technology to minimize the risk of sparks during connection.

Easy to Solder:

- Soldering tabs are designed for easy soldering, making them user-friendly for hobbyists and professionals alike.

Polarity Protection:

- Ensures correct polarity connection, preventing damage to electronic components.

Applications

Drones:

- Widely used in connecting LiPo batteries to ESCs, ensuring reliable power supply for motors.

Electric Scooters:

- Used in battery management systems and motor controllers, providing efficient and safe power connections.

RC Vehicles:

- Commonly found in remote-controlled cars, boats, and planes, providing reliable connections between batteries and motors.

DIY Electronics Projects:

- Favored by hobbyists for various custom electronic builds requiring robust power connections.

Solar Power Systems:

- Utilized in connecting solar panels and batteries, ensuring efficient power transfer in renewable energy setups.

Robotics:

- Used in robotic systems to connect various power modules, ensuring stable and reliable power distribution.

Advantages and Disadvantages

Advantages:

- High Current Handling: Capable of handling high currents, making them suitable for demanding applications.

- Durability: Made from high-quality materials that withstand high temperatures and mechanical stress.

- Low Resistance: Gold-plated connectors ensure efficient power transfer.

- Secure Fit: Tight connection prevents accidental disconnections.

- Polarity Protection: Reduces the risk of damaging electronic components due to incorrect connections.

Disadvantages:

- Size and Weight: Larger connectors (XT60 and XT90) can be bulky and heavy for some applications, especially where space and weight are critical.

- Cost: Higher quality and reliability come at a higher cost compared to cheaper, lower-quality connectors.

- Soldering Skill Required: Proper soldering skills are required to ensure secure and efficient connections, which might be a barrier for beginners.

T-plug Connector

The T-plug, also known as the Deans connector, is a popular type of electrical connector commonly used in radio-controlled (RC) models and other hobbyist electronics. Developed by Deans, these connectors are designed to provide a stable and efficient connection between batteries and electronic components. The T-plug is named for its distinctive T-shaped design, which ensures a secure fit and easy handling.

Features

Stable Connection:

- Provides a reliable and low-resistance connection, which is essential for high-current applications in RC models and drones.

Easy to Plug and Remove:

- The T-shaped design allows for easy insertion and removal, facilitating quick battery changes and maintenance.

Compact Size:

- Small and lightweight, making it suitable for applications where space and weight are critical factors.

Gold-Plated Contacts:

- Features gold-plated connectors that ensure low resistance and prevent corrosion, enhancing conductivity and longevity.

High Current Capacity:

- Capable of handling high current loads, typically up to 60A, making it suitable for power-intensive applications.

Polarized Design:

- Ensures correct polarity connection, reducing the risk of damaging electronic components due to incorrect connections.

Heat Resistance:

- Constructed from materials that can withstand high temperatures, ensuring performance stability even under heavy loads.

Applications

RC Equipment:

- Widely used in remote-controlled cars, boats, planes, and helicopters to connect batteries, motors, and speed controllers.

Drones:

- Employed in drones to connect batteries to flight controllers and other electronic components, ensuring reliable power supply.

Electric Vehicles:

- Used in small electric vehicles and scooters for connecting battery packs and power systems.

Hobbyist Electronics:

- Favored by hobbyists for DIY electronics projects that require secure and efficient power connections.

Battery Packs:

- Commonly used to connect rechargeable battery packs in various applications, ensuring stable and reliable power delivery.

Advantages and Disadvantages

Advantages:

- Stable and Reliable: Provides a secure and low-resistance connection, essential for high-performance applications.

- Easy Handling: The T-shaped design makes it easy to plug in and remove, facilitating quick battery swaps and maintenance.

- Compact and Lightweight: Ideal for applications where space and weight are critical, such as in RC models and drones.

- Durable Contacts: Gold-plated connectors ensure long-lasting performance with minimal resistance and corrosion.

- High Current Handling: Suitable for high-current applications, supporting up to 60A.

- Correct Polarity: Polarized design prevents incorrect connections, protecting electronic components from damage.

Disadvantages:

- Wear and Tear: Repeated plugging and unplugging can cause wear on the connectors, potentially affecting performance over time.

- Heat Generation: Under very high current loads, connectors may generate heat, which could affect performance if not managed properly.

- Compatibility Issues: Not universally compatible with all types of connectors, requiring careful selection to ensure compatibility with other components.

- Soldering Required: Installation typically requires soldering, which might be a barrier for beginners or those without soldering equipment and skills.

EC2, EC3, EC5, EC6, and EC8 Battery Connectors

EC (Electric Connector) series battery connectors, including EC2, EC3, EC5, EC6, and EC8, are popular connectors used in various high-power applications such as electric aircraft, drones, and RC vehicles. These connectors are known for their high current carrying capacity, low resistance, and reliable connections. They are designed to ensure efficient power transfer and secure connections in demanding environments.

Features

High Current Carrying Capacity:

- EC2: Designed for low to moderate current applications, typically up to 20A.

- EC3: Suitable for moderate current applications, typically up to 60A.

- EC5: Handles higher currents, typically up to 120A.

- EC6: Capable of handling even higher currents, typically up to 150A.

- EC8: Designed for very high current applications, typically up to 200A.

Low Resistance:

- All EC connectors are designed with low contact resistance to ensure efficient power transfer and minimize energy losses. This is often achieved through the use of high-quality materials and gold-plated contacts.

Robust Construction:

- Made from durable materials that can withstand mechanical stress, high temperatures, and environmental factors. The connectors are designed to maintain integrity under harsh conditions.

Secure Connection:

- Equipped with reliable locking mechanisms to prevent accidental disconnections. The connectors fit snugly and securely, ensuring stable power delivery.

Ease of Use:

- The connectors are designed for easy connection and disconnection, often with ergonomic grips and foolproof alignment features.

Modularity:

- EC connectors are modular, allowing for easy replacement and customization in various applications. This makes them versatile and adaptable to different power needs.

Applications

Electric Aircraft:

- Used to connect battery packs to motors, ESCs (Electronic Speed Controllers), and other electrical components in electric aircraft. Their high current capacity ensures reliable power delivery during flight.

Drones:

- Commonly used in drones for connecting battery packs to motors and other electronic components. Their secure connection and high current handling make them ideal for high-performance drones.

RC Vehicles:

- Widely used in remote-controlled cars, boats, and helicopters. The connectors provide the necessary power for high-speed and high-power RC applications.

Electric Bikes and Scooters:

- Employed in electric bikes and scooters to connect batteries to motors and controllers, ensuring efficient power transfer for propulsion.

Battery Packs:

- Used in assembling custom battery packs for various applications, including hobbyist projects and professional-grade equipment.

Power Tools:

- Suitable for high-power cordless tools, providing reliable connections between batteries and tool motors.

Advantages and Disadvantages

Advantages:

- High Power Handling: Capable of carrying high currents, making them suitable for demanding applications.

- Efficient Power Transfer: Low contact resistance ensures minimal energy loss and efficient power delivery.

- Durable and Reliable: Robust construction and secure locking mechanisms ensure long-term reliability even in harsh conditions.

- Versatile and Modular: Can be used in a wide range of applications and easily replaced or customized as needed.

- Easy to Use: Designed for straightforward connection and disconnection, reducing installation time and effort.

Disadvantages:

- Cost: Higher quality connectors can be expensive, especially those designed for very high currents.

- Size and Weight: Higher current models (EC6, EC8) can be bulky and heavy, which may be a limitation in space-constrained applications.

- Complexity: Installing and soldering these connectors can be complex and may require specific tools and skills.

- Availability: Genuine connectors may be harder to find and more expensive compared to lower-quality imitations.

Anderson Powerpole Connector for Battery

Anderson Powerpole connectors are a versatile and widely used type of electrical connector designed for high-current applications. Developed by Anderson Power Products, these connectors are known for their durability, reliability, and ease of use. They are commonly used in various industries, including renewable energy, telecommunications, and emergency power systems. The Powerpole connectors are available in various sizes and current ratings, allowing them to be tailored to specific applications.

Features

High Current Carrying Capacity:

- Capable of handling currents ranging from 15A to over 350A, depending on the specific connector size and model.

Modular Design:

- The connectors can be stacked and arranged in various configurations, allowing for customization to meet specific needs.

- Genderless design means that there is no male or female side, simplifying connections and reducing the risk of mismating.

Durable Construction:

- Made from high-quality materials, such as high-impact thermoplastic housings and silver- or tin-plated copper contacts, ensuring long-lasting performance.

- High resistance to vibration and impact, making them suitable for rugged environments.

Low Resistance:

- Silver-plated contacts provide low electrical resistance, ensuring efficient power transfer and minimal heat generation.

Color-Coded Housings:

- Available in a range of colors, allowing for easy identification and organization of connections.

Tool-less Assembly:

- Snap-lock design allows for quick and easy assembly and disassembly without the need for special tools.

Safety Features:

- Incorporates features such as finger-proof housings and keying options to prevent incorrect connections and enhance safety.

Applications

Solar Energy Systems:

- Used to connect solar panels, batteries, and inverters, providing reliable and efficient power transfer in renewable energy setups.

Emergency Power Supplies:

- Commonly used in backup power systems, including UPS systems and portable generators, ensuring reliable connections during power outages.

Telecommunications:

- Employed in telecom infrastructure for connecting backup batteries and power distribution units, ensuring continuous power supply.

Electric Vehicles:

- Utilized in electric vehicle charging stations and battery packs, providing secure and efficient power connections.

Amateur Radio:

- Popular among amateur radio operators for connecting power supplies and radios, ensuring consistent and reliable power delivery.

Industrial Automation:

- Used in various industrial applications, including robotics and automation systems, for connecting power modules and equipment.

Advantages and Disadvantages

Advantages:

- High Current Handling: Suitable for a wide range of applications requiring high current.

- Modular and Versatile: Easily customizable for different configurations and uses.

- Durability: Robust construction ensures long-term reliability and performance.

- Ease of Use: Simple assembly and disassembly without the need for special tools.

- Safety: Incorporates features to prevent incorrect connections and enhance safety.

- Color-Coding: Simplifies organization and identification of connections.

Disadvantages:

- Cost: Generally more expensive than some other types of connectors, especially for high-current models.

- Size: Larger sizes can be bulky, which may be a limitation in space-constrained applications.

- Availability: While popular, they may not be as widely available as more common connectors in some regions.

- Contact Wear: Over time, repeated connecting and disconnecting can cause wear on the contacts, potentially affecting performance.

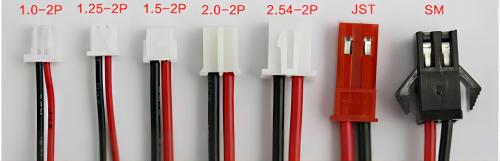

JST Connector For Battery

JST connectors, manufactured by the Japanese company JST (Japan Solderless Terminals), are a popular type of electrical connector used in a wide variety of electronic applications. Known for their compact size and reliability, JST connectors are widely utilized in consumer electronics, hobbyist projects, and industrial applications. These connectors come in various series, each designed for specific current ratings and use cases, making them a versatile choice for many electronic devices.

Features

Miniaturization:

- Designed to be small and lightweight, making them ideal for compact electronic devices where space is limited.

Variety of Series:

- Available in numerous series such as JST-XH, JST-PH, JST-SH, and JST-RE, each tailored for different pin pitches, current ratings, and applications.

Low Cost:

- Economically priced, making them accessible for both large-scale manufacturing and hobbyist use.

Ease of Use:

- Simple design allows for easy assembly and disassembly, often without the need for special tools.

- Polarized connectors prevent incorrect mating, ensuring reliable connections.

Reliable Connections:

- Secure locking mechanism provides a reliable electrical connection, reducing the risk of accidental disconnections.

Wide Range of Pin Configurations:

- Available in configurations from single pin to multi-pin connectors, accommodating different wiring needs.

High Density:

- Designed to support high-density connections, allowing more connections in a smaller footprint.

Applications

Remote Control Toys:

- Frequently used in RC cars, drones, and helicopters to connect batteries, motors, and other electronic components.

Small Appliances:

- Utilized in small household appliances such as electric toothbrushes, shavers, and kitchen gadgets for connecting internal circuitry.

Consumer Electronics:

- Commonly found in devices like cameras, gaming consoles, and handheld gadgets for internal connections.

Wearable Technology:

- Used in smartwatches, fitness trackers, and other wearable devices due to their compact size and reliable connections.

LED Lighting:

- Employed in LED strips and lighting systems for secure and easy connections between components.

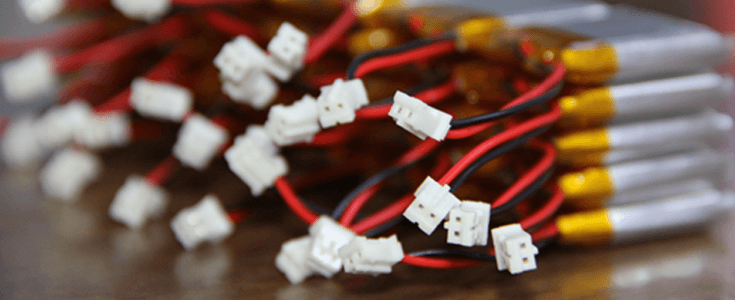

Battery Packs:

- Widely used in battery packs for laptops, smartphones, and other portable electronic devices to connect cells and protection circuits.

Industrial Equipment:

- Found in various industrial applications, including sensors and small machinery, where reliable and compact connections are required.

Advantages and Disadvantages

Advantages:

- Compact Size: Ideal for applications where space is at a premium.

- Cost-Effective: Low cost makes them suitable for both mass production and individual projects.

- Variety: Wide range of series and configurations to meet different application requirements.

- Ease of Use: Simple design and polarized connectors ensure easy and correct connections.

- Reliable: Secure locking mechanisms provide stable and reliable connections.

Disadvantages:

- Current Capacity: Generally designed for low to moderate current applications, which may not be suitable for high-power requirements.

- Durability: Some series may not be as robust as other types of connectors, especially in high-vibration or harsh environments.

- Limited High-Power Options: While there are high-power JST connectors available, they are less common and might not meet the needs of all high-power applications.

- Contact Wear: Repeated connecting and disconnecting can wear down the contacts over time, potentially affecting performance.

Molex Connector for Battery

Molex connectors, developed by the company Molex, are a widely used type of electrical connector known for their reliability and versatility. Since their introduction, Molex connectors have become a standard in various industries, providing dependable connections for power and data. They are available in a vast array of configurations, sizes, and contact materials, making them suitable for a multitude of applications, including battery connections in electronic devices.

Features

High Reliability:

- Designed to provide a secure and stable connection, minimizing the risk of accidental disconnection and ensuring consistent performance.

Wide Range of Applications:

- Available in various series such as Mini-Fit, Micro-Fit, and Mega-Fit, each catering to different current ratings, voltage requirements, and physical sizes.

Robust Construction:

- Made from durable materials that can withstand mechanical stress and environmental factors, ensuring longevity and reliability.

Variety of Configurations:

- Comes in multiple configurations, including single-row and double-row connectors, with varying numbers of pins to suit different application needs.

Ease of Use:

- Often features easy-to-use locking mechanisms that ensure a secure connection without the need for specialized tools.

- Designed for both wire-to-wire and wire-to-board applications.

High Current and Voltage Ratings:

- Capable of handling high currents and voltages, suitable for power-intensive applications such as battery connections in power tools and computers.

Customizable:

- Offers options for customization to meet specific application requirements, including different pin counts, orientations, and contact plating.

Applications

Computers:

- Widely used in connecting internal components such as motherboards, power supplies, and peripheral devices.

Power Tools:

- Utilized in battery connections for power tools, providing reliable and efficient power transfer.

Automotive:

- Employed in various automotive applications, including battery connections, lighting, and infotainment systems.

Consumer Electronics:

- Common in a range of consumer electronics, including gaming consoles, cameras, and home appliances.

Industrial Equipment:

- Used in industrial machinery and equipment for power and signal connections, ensuring reliable operation in demanding environments.

Telecommunications:

- Utilized in telecom infrastructure for connecting power supplies and communication equipment.

Medical Devices:

- Found in medical equipment where reliable and secure connections are critical for safety and performance.

Advantages and Disadvantages

Advantages:

- High Reliability: Ensures stable and secure connections, reducing the risk of failures.

- Versatility: Wide range of configurations and customization options make them suitable for various applications.

- Durability: Robust construction withstands environmental and mechanical stress, ensuring long-term performance.

- Ease of Use: Simple and secure locking mechanisms provide easy and reliable connections without specialized tools.

- High Current and Voltage Handling: Suitable for power-intensive applications.

Disadvantages:

- Cost: Generally more expensive than some other types of connectors, which might be a consideration for budget-sensitive projects.

- Size: Larger connectors can be bulky, which may be a limitation in space-constrained applications.

- Complexity: The wide variety of options and configurations can be overwhelming, requiring careful selection to meet specific needs.

- Contact Wear: Repeated connecting and disconnecting can lead to wear on the contacts, potentially affecting performance over time.

Car Battery Connector

Automotive battery connectors are crucial components used in vehicles to connect the battery to the electrical system. These connectors ensure that the battery can provide the necessary power to start the engine and operate the vehicle's electrical systems. Designed to handle high currents and harsh environmental conditions, automotive battery connectors play a vital role in vehicle reliability and performance.

Features

High Current Carrying Capacity:

- Engineered to handle the high current demands of automotive applications, typically ranging from hundreds to thousands of amperes.

Durability:

- Constructed from robust materials such as brass or lead, often with protective coatings to resist corrosion and wear.

- Designed to withstand the harsh conditions of automotive environments, including temperature extremes, vibration, and exposure to chemicals.

Secure Connection:

- Features such as bolt-on terminals or clamp mechanisms ensure a tight and secure connection to the battery posts, minimizing the risk of disconnection or poor contact.

Ease of Installation:

- Designed for straightforward installation and removal, often without the need for specialized tools.

- Standardized sizes and shapes make them compatible with a wide range of battery types.

Safety Features:

- Some connectors include insulating covers or caps to protect against accidental short circuits and to enhance safety during installation and maintenance.

Polarity Protection:

- Clearly marked positive (+) and negative (-) terminals to prevent incorrect connections, which can cause damage to the vehicle's electrical system.

Applications

Car Starting:

- Primary use in connecting the car battery to the starter motor, providing the necessary power to start the engine.

Battery Pack Connection:

- Used in connecting multiple battery cells in electric and hybrid vehicles, ensuring efficient power distribution.

Vehicle Electrical Systems:

- Connects the battery to the vehicle's electrical system, powering lights, infotainment systems, and other electronic components.

Charging Systems:

- Integral in connecting the battery to the vehicle's alternator and charging system, ensuring the battery remains charged during operation.

Aftermarket Accessories:

- Used for connecting additional accessories such as winches, aftermarket lighting, and audio systems directly to the battery.

Advantages and Disadvantages

Advantages:

- High Current Handling: Capable of managing the significant power requirements of automotive applications.

- Durability: Built to withstand the demanding conditions of automotive environments, ensuring long-term reliability.

- Secure and Reliable: Designed to provide a stable connection, reducing the risk of power loss or disconnection.

- Ease of Use: Simple installation and removal processes, often without the need for specialized tools.

- Safety: Includes features to prevent accidental short circuits and ensure correct polarity connections.

Disadvantages:

- Corrosion: Despite protective coatings, connectors can still be prone to corrosion over time, particularly in harsh environments.

- Size and Bulk: The robust construction and high current capacity can result in larger and bulkier connectors, which may be a limitation in compact spaces.

- Maintenance: Requires regular inspection and maintenance to ensure continued performance and prevent issues such as loose connections or corrosion.

- Cost: High-quality connectors with advanced features and materials can be more expensive compared to simpler, less robust options.

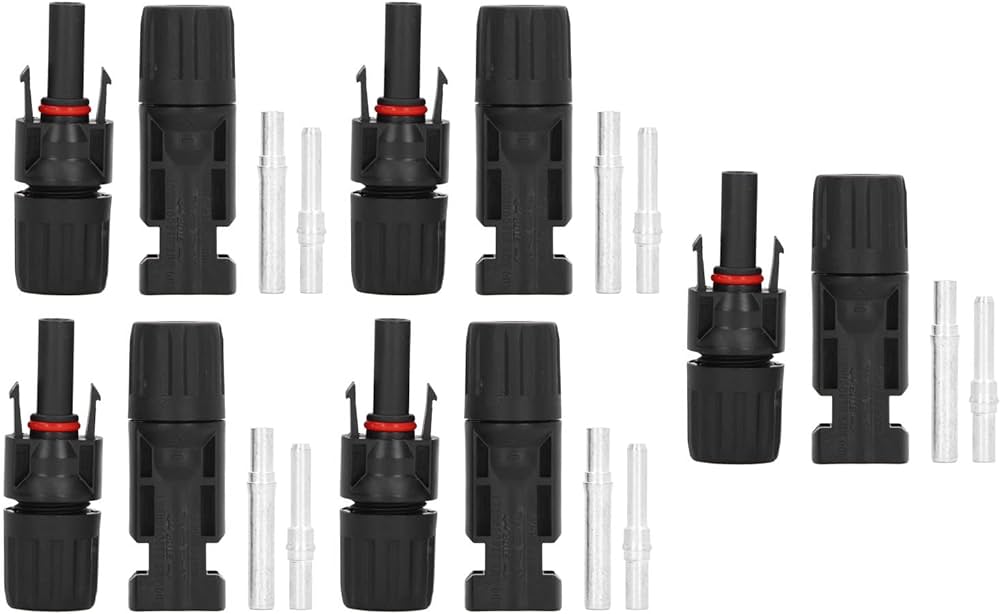

Solar Power Battery Connector

Solar power battery connectors are specialized connectors designed for use in photovoltaic (PV) power generation and energy storage systems. These connectors play a crucial role in connecting solar panels to batteries and other components of a solar power system, ensuring efficient and reliable power transfer. Designed to handle high voltages and withstand harsh environmental conditions, solar power battery connectors are essential for the longevity and performance of solar energy systems.

Features

Weather Resistance:

- Constructed with materials that resist UV radiation, moisture, and extreme temperatures, ensuring durability and reliability in outdoor environments.

High Voltage Carrying Capacity:

- Engineered to handle the high voltages generated by solar panels, typically ranging from 600V to 1500V, depending on the system design.

High Current Handling:

- Capable of carrying substantial currents required for efficient energy transfer between solar panels and batteries.

Secure Connection:

- Features robust locking mechanisms that ensure a secure and stable connection, minimizing the risk of accidental disconnections.

Safety Features:

- Often include safety features such as touch-proof designs and polarity protection to prevent electrical accidents and ensure correct connections.

Ease of Installation:

- Designed for easy and quick installation, often with tool-less or easy-to-use crimping and assembly methods.

Low Contact Resistance:

- Ensures efficient power transfer with minimal energy loss, enhancing the overall efficiency of the solar power system.

Modularity:

- Available in various configurations to accommodate different system sizes and setups, including single and multi-pole connectors.

Applications

Photovoltaic Power Generation Systems:

- Used to connect solar panels to inverters, charge controllers, and other system components, ensuring efficient power generation and distribution.

Energy Storage Systems:

- Connects batteries to solar panels and inverters, facilitating the storage and use of solar energy.

Off-Grid Solar Systems:

- Utilized in standalone solar power systems for remote areas, providing reliable connections between solar panels, batteries, and other system components.

Residential Solar Installations:

- Integral in home solar power setups, connecting rooftop solar panels to inverters and battery storage units.

Commercial and Industrial Solar Projects:

- Used in large-scale solar power installations for businesses and industrial facilities, ensuring efficient and reliable power transfer.

Electric Vehicle Charging Stations:

- Connects solar panels to battery storage units and charging stations, enabling the use of solar energy for vehicle charging.

Advantages and Disadvantages

Advantages:

- Weather Resistance: Designed to withstand harsh outdoor conditions, ensuring long-term durability and reliability.

- High Voltage and Current Handling: Capable of managing the high voltages and currents typical of solar power systems, ensuring efficient energy transfer.

- Secure and Stable Connections: Robust locking mechanisms prevent accidental disconnections, enhancing system reliability.

- Safety Features: Built-in safety features such as touch-proof designs and polarity protection enhance user safety.

- Efficiency: Low contact resistance ensures minimal energy loss, maximizing the efficiency of the solar power system.

- Ease of Installation: User-friendly design allows for quick and easy installation, reducing labor and time costs.

Disadvantages:

- Cost: High-quality solar connectors can be expensive, increasing the overall cost of the solar power system.

- Maintenance: Regular inspection and maintenance are required to ensure ongoing reliability and performance, particularly in harsh environments.

- Compatibility: Ensuring compatibility between different brands and types of connectors can be challenging, necessitating careful selection and verification.

- Size: Some high-capacity connectors can be bulky, which may be a limitation in compact installations.

9V Battery Clip Connector

The 9V battery clip connector is a simple and widely used electrical connector designed to connect 9V batteries to electronic circuits and devices. These connectors typically feature a pair of snaps (one male and one female) that securely attach to the terminals of a 9V battery. They are commonly used in a variety of low-power applications, providing a convenient and reliable way to power small electronic projects and devices.

Features

Stable Connection:

- Provides a secure connection to the 9V battery terminals, ensuring consistent power delivery without risk of accidental disconnection.

Easy to Use:

- The simple design allows for quick and easy attachment and detachment to the battery terminals without the need for tools.

- Typically includes a pair of wires (red for positive and black for negative) for easy integration into circuits.

Flexible Wires:

- Usually equipped with flexible wires, making it easy to connect to various components and allowing for a range of movement without disconnecting.

Compact Design:

- Small and lightweight, ideal for portable and space-constrained applications.

Polarity Protection:

- The snap design ensures correct polarity connection, reducing the risk of damaging electronic components due to incorrect connections.

Cost-Effective:

- Inexpensive and widely available, making them a popular choice for hobbyists and educational purposes.

Applications

Electronic Projects:

- Commonly used in DIY electronics projects, breadboarding, and prototyping to provide a reliable power source.

Toys:

- Frequently found in battery-powered toys, providing a simple and secure method to connect 9V batteries.

Educational Kits:

- Utilized in educational electronics kits for students and beginners, allowing easy assembly and power connection.

Portable Devices:

- Used in various small, portable devices that require a 9V battery for power.

Testing Equipment:

- Employed in testing and diagnostic equipment that operates on 9V batteries, offering a quick and reliable power connection.

Advantages and Disadvantages

Advantages:

- Stable Connection: Ensures a reliable and secure connection to the battery, preventing power interruptions.

- Ease of Use: Quick and easy to connect and disconnect, making it user-friendly for both beginners and experienced users.

- Cost-Effective: Low cost makes it accessible for a wide range of applications, including educational and hobbyist projects.

- Compact and Lightweight: Small size and lightweight are ideal for portable and space-constrained applications.

- Polarity Protection: Snap design ensures correct polarity, protecting electronic components from damage.

Disadvantages:

- Limited Current Capacity: Suitable for low-current applications; not ideal for high-power devices.

- Wear and Tear: Repeated use can lead to wear and tear on the snaps, potentially affecting the quality of the connection over time.

- Limited Durability: Not as durable as some other connectors, especially in high-stress or high-vibration environments.

- Fixed Length Wires: The fixed length of the wires may limit flexibility in some applications, requiring extensions or modifications.

SAE Battery Connector

SAE (Society of Automotive Engineers) battery connectors are standardized connectors widely used in automotive, motorcycle, and other vehicular applications. These connectors are designed to provide a reliable and durable connection between batteries and electrical systems, facilitating easy battery maintenance and accessory connections. The standardized design ensures compatibility across various devices and vehicles, making SAE connectors a popular choice in the automotive industry.

Features

Reliable Connection:

- Designed to provide a stable and secure connection, ensuring consistent power delivery and minimizing the risk of accidental disconnections.

Standardized Design:

- Adheres to SAE standards, ensuring compatibility and interchangeability between different brands and devices.

Polarity Protection:

- The connectors are polarized, preventing incorrect connections that could damage electrical systems.

Durability:

- Constructed from high-quality materials that can withstand harsh automotive environments, including exposure to oil, grease, and high temperatures.

Ease of Use:

- Features a simple plug-and-play design, making it easy to connect and disconnect without the need for tools.

- Often includes protective caps to prevent dirt and moisture from entering the connector when not in use.

Versatility:

- Available in various configurations, including single and double connectors, to accommodate different applications and power needs.

Weather Resistance:

- Many SAE connectors come with weatherproof features, such as rubber seals, to protect against moisture and corrosion.

Applications

Automotive:

- Commonly used in cars and trucks to connect battery maintainers, chargers, and accessories such as GPS units and auxiliary lights.

Motorcycle:

- Used to connect batteries to chargers, heated gear, and other accessories, ensuring reliable power supply and easy battery maintenance.

Battery Maintenance:

- Ideal for connecting battery maintainers and trickle chargers to keep vehicle batteries in optimal condition during periods of inactivity.

Recreational Vehicles (RVs):

- Used in RVs for connecting batteries to solar panels, inverters, and other power management systems.

Marine:

- Employed in boats and marine applications for connecting batteries to onboard electrical systems and accessories.

Solar Power Systems:

- Utilized in small solar power setups to connect solar panels to batteries and charge controllers.

Portable Power Packs:

- Used in portable battery packs and jump starters for easy and reliable connection to vehicle batteries.

Advantages and Disadvantages

Advantages:

- Reliable Connection: Ensures a stable and secure connection, providing consistent power delivery for various applications.

- Ease of Use: Simple plug-and-play design allows for quick and easy connections without the need for tools.

- Standardized and Compatible: Adheres to SAE standards, ensuring compatibility and interchangeability across different brands and devices.

- Durable and Weather-Resistant: Built to withstand harsh environments, including exposure to moisture, oil, and high temperatures.

- Versatile: Suitable for a wide range of applications, from automotive and motorcycles to marine and solar power systems.

- Polarity Protection: Polarized design prevents incorrect connections, protecting electrical systems from damage.

Disadvantages:

- Limited Current Capacity: Typically designed for low to moderate current applications, which may not be suitable for high-power devices.

- Exposure to Elements: While some connectors are weather-resistant, others may require additional protection to prevent corrosion and damage from environmental exposure.

- Potential for Wear and Tear: Repeated plugging and unplugging can lead to wear and tear on the connectors, potentially affecting performance over time.

- Fixed Length: The fixed length of the connector wires may limit flexibility in certain installations, requiring extensions or modifications.

New Energy Battery Connector

New energy battery connectors are advanced electrical connectors designed to meet the demanding requirements of modern energy applications, such as electric vehicles (EVs) and energy storage systems (ESS). These connectors are engineered to handle high currents and voltages, ensuring efficient and reliable power transfer in applications that prioritize sustainability and renewable energy sources. As the global focus shifts toward reducing carbon emissions and increasing the use of renewable energy, new energy battery connectors play a critical role in facilitating these technologies.

Features

High Current and Voltage Carrying Capacity:

- Designed to handle the high currents (often exceeding 200A) and voltages (up to 1000V or more) required in EVs and large energy storage systems.

Robust Construction:

- Made from high-quality, durable materials that can withstand mechanical stress, high temperatures, and harsh environmental conditions.

Safety Features:

- Equipped with safety mechanisms such as touch-proof designs, interlocks, and temperature sensors to prevent accidental disconnections and overheating.

Low Contact Resistance:

- Engineered to have minimal contact resistance, ensuring efficient power transfer and reducing energy losses.

Thermal Management:

- Incorporates advanced thermal management features to dissipate heat effectively, ensuring reliable performance under heavy load conditions.

Ease of Use:

- Designed for easy and secure connection and disconnection, often with ergonomic grips and foolproof alignment features.

Compatibility:

- Standardized designs to ensure compatibility with a wide range of batteries and power systems, facilitating easier integration.

Environmental Resistance:

- Built to resist moisture, dust, chemicals, and other environmental factors, ensuring longevity and reliability in various conditions.

Applications

Electric Vehicles (EVs):

- Used to connect the battery packs to the vehicle’s powertrain, charging systems, and other electrical components, ensuring efficient power delivery.

Energy Storage Systems (ESS):

- Integral in connecting battery modules in large-scale energy storage installations, facilitating the storage and distribution of renewable energy.

Renewable Energy Systems:

- Applied in solar and wind power systems to connect batteries and other storage devices, ensuring stable and reliable energy supply.

Industrial Applications:

- Utilized in various industrial machines and equipment that require high power, such as forklifts and heavy machinery.

Grid-Connected Systems:

- Employed in systems that connect energy storage to the power grid, helping to balance supply and demand and improve grid stability.

Marine and Aerospace:

- Used in electric boats, ships, and aircraft, where high-performance and reliable battery connections are critical.

Advantages and Disadvantages

Advantages:

- High Power Handling: Capable of carrying high currents and voltages, making them suitable for demanding energy applications.

- Efficiency: Low contact resistance ensures efficient power transfer with minimal energy loss.

- Durability: Robust construction and environmental resistance ensure long-term reliability in harsh conditions.

- Safety: Advanced safety features protect against accidental disconnections, overheating, and electrical faults.

- Ease of Use: Ergonomic and foolproof designs facilitate easy and secure connections, reducing installation time and errors.

- Standardization: Ensures compatibility and ease of integration with various batteries and power systems.

Disadvantages:

- Cost: High-quality connectors with advanced features can be expensive, increasing the overall cost of the system.

- Complexity: Advanced features and safety mechanisms may add complexity to the design and usage of the connectors.

- Size and Weight: High-capacity connectors can be bulky and heavy, which may be a limitation in compact or weight-sensitive applications.

- Maintenance: Requires regular inspection and maintenance to ensure ongoing reliability and performance, especially in critical applications.

Select the appropriate connector

Selecting the appropriate battery connector is crucial for ensuring optimal performance and safety in various applications. When choosing a connector, several factors need to be considered, such as current requirements, voltage requirements, physical space constraints, connection reliability, environmental conditions, and more.

1. Current Requirements:

- Determine the Maximum Current: Identify the peak current your application will draw. Ensure the connector can handle this maximum current without overheating or significant voltage drops.

- Continuous vs. Peak Current: Ensure the connector can handle both continuous and peak current ratings.

2. Voltage Requirements:

- Voltage Rating: Select connectors rated for higher than your maximum operating voltage to provide a safety margin and ensure reliability.

3. Physical Space Constraints:

- Size and Weight: Consider the size and weight of the connector, especially for applications where space and weight are critical, such as drones and portable devices.

- Form Factor: Ensure the connector's form factor fits within the physical space available in your design.

4. Connection Reliability:

- Secure Connection: Look for connectors with robust locking mechanisms to prevent accidental disconnections, especially in applications subject to vibrations and movements.

- Low Resistance Contacts: Choose connectors with low resistance contacts, such as gold-plated pins, to ensure efficient power transfer and reduce energy losses.

5. Environmental Conditions:

- Temperature Range: Ensure the connector can operate reliably within the temperature range of your application.

- Weather Resistance: For outdoor and harsh environment applications, select connectors with weatherproof features, such as IP-rated sealing, to protect against moisture, dust, and corrosion.

6. Ease of Use:

- User-Friendly Design: Choose connectors that are easy to connect and disconnect, especially if frequent maintenance or battery swaps are required.

- Polarized Connectors: Select polarized connectors to prevent incorrect connections and potential damage to your components.

7. Application-Specific Requirements:

- Special Features: Consider any special requirements of your application, such as high flexibility for robotic arms or specific standards compliance for automotive or aerospace use.

Practical Advice for Purchasing Connectors

Brand Recommendations:

- Established Brands: Opt for connectors from reputable manufacturers known for high-quality products, such as Amphenol, Molex, TE Connectivity, Anderson Power Products, and XT series manufacturers.

- Product Reviews: Look for reviews and recommendations from other users in your specific application area to find reliable and well-regarded connectors.

Quality Inspection:

- Visual Inspection: Check for any visible defects, such as cracks, deformities, or poor molding.

- Material Quality: Ensure connectors are made from high-quality materials that meet your application's requirements for durability and performance.

- Contact Quality: Inspect the contact surfaces for plating quality (e.g., gold-plated for low resistance) and ensure there are no signs of oxidation or corrosion.

- Mechanical Fit: Test the mechanical fit and locking mechanism to ensure a secure and reliable connection.

Purchase Considerations:

- Quantity: Buy connectors in bulk if you have large-scale needs, but start with a small batch for testing if trying a new type.

- Supplier Reliability: Purchase from reputable suppliers or authorized distributors to avoid counterfeit or substandard products.

- Warranty and Support: Choose suppliers that offer warranties and technical support to assist with any issues that may arise.

Example Recommendations

High-Current Applications:

- XT60/XT90: Excellent for high-current applications like drones and RC vehicles. Ensure connectors are genuine to avoid low-quality imitations.

- EC5/EC6: Suitable for high-current and high-voltage applications, providing secure and reliable connections for electric aircraft and larger drones.

Automotive and Motorcycle:

- SAE Connectors: Ideal for battery maintainers and accessory connections. Ensure weatherproof features for outdoor use.

- Anderson Powerpole: Versatile and reliable for a wide range of automotive and motorcycle applications, with easy modularity.

Small Electronics and Toys:

- JST Connectors: Perfect for low-current, space-constrained applications like small electronics and RC toys. Ensure proper polarity to avoid damage.

Industrial and Renewable Energy:

- Amphenol Connectors: High-quality, robust connectors suitable for industrial machinery and renewable energy systems. Look for specific models rated for high voltage and environmental protection.

- Molex Connectors: Versatile options for various applications, including solar power systems and energy storage solutions.

About Us

How to Customize Your Battery Connector Cable?

Send your sample or drawing/schematic for quote price→ Feedback with quotation(1~3 days) → Confirm quotation → Arrange sample you for approval→ [Make mold if needed (7 days) →Mold test] → Making samples(1~3 days)→Samples test(Approval) →place order for Mass production(2~3 weeks)→Quality checking→Packing →Delivery →After Service →Repeat Order.